Stay safe with this guide to the facts and stats about silica dust, a common construction and railway hazard.

What is silica?

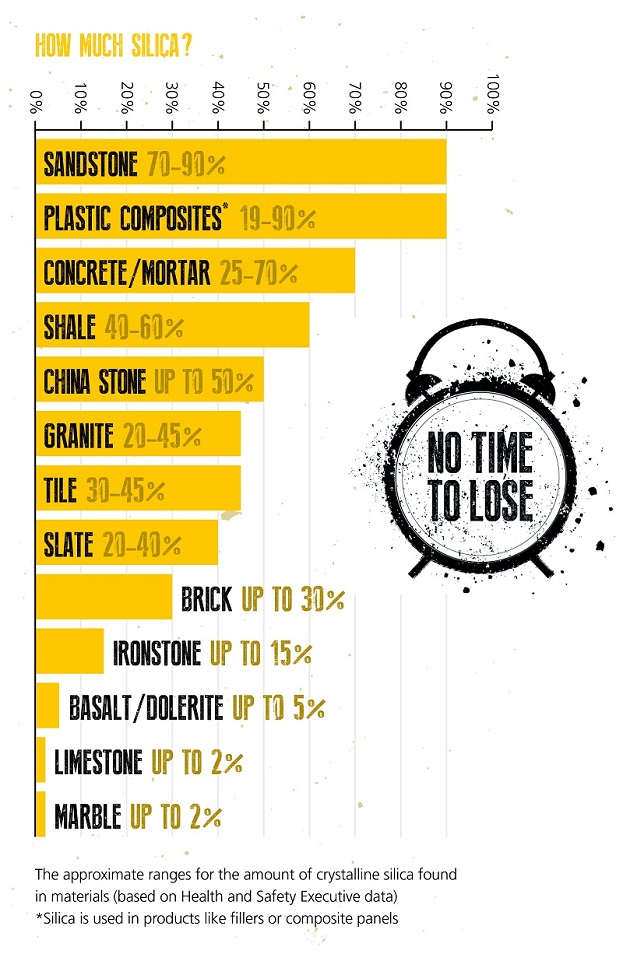

Silica is a natural substance in most rocks (including slate), sand, clay and anything made from these, such as ballast, bricks, tiles, mortar or concrete.

Cutting, drilling or otherwise working on these materials releases silica dust. Silica dust is very fine and can be almost invisible. This means dust levels can be dangerously high without it being obvious. If you breathe in small particles of the dust they pass through your nose or mouth into your lungs.

How can silica be harmful?

Silica, in particular Respirable Crystalline Silica (RCS), is harmful when it is breathed in as very fine dust particles that go deep into the lungs, where your body takes up oxygen into your blood. Sitting on a sandy beach is not a cause for concern! Sand grains are too large to go past your nose or upper airways. If silica dust is not managed appropriately in the workplace, there is a risk of lung cancer and silicosis as well as other lung diseases such as emphysema and bronchitis.

Research from Imperial College London in 2012 suggested that around 900 new cases of lung cancer in Britain each year are linked to past exposure to silica dust. People with silicosis may have a higher risk of lung cancer. Silicosis symptoms include a persistent cough, shortness of breath, weakness and tiredness.

In 2021, the Health and Safety Executive (HSE) found that 12,000 deaths each year in the UK are estimated to be linked to past exposure to dust and chemicals at work, but it expects the actual number of cases to be much higher than this because of under-reporting.

When might I be exposed to silica dust?

Every year, an estimated 600,000 workers are exposed to silica in the UK. You might be exposed to silica dust if your work involves:

- laying, maintaining or replacing ballast

- breaking, crushing, grinding or milling concrete, aggregate, mortar or other silica-containing materials

- drilling, cutting, chiselling or sanding silica-containing materials

- working with cement

- moving earth (excavating, mining, quarrying or tunnelling)

- abrasive blasting or sandblasting

- handling, mixing or shovelling dry materials that include silica

- dry sweeping up after a task where silica dust has been created.

Even after a task is completed, the dust can stay in the air, be on clothes and surfaces, be disturbed by people or vehicles and become airborne, or be released when equipment leaks or there is a spill. Certain jobs are more likely to be exposed to silica dust than others – for example, bricklayers and stonemasons.

How can I protect myself?

- Use local exhaust ventilation – a ventilation system will suck the dust away before you can breathe it in.

- Operate on-tool extraction – use the controls integrated or mounted on to a hand-held tool to capture dust as you are using it.

- Damp down dust – keep dust levels down with water, but you need enough water for the whole time that you are doing the work. You can also control the dust during the task using an industrial vacuum.

- Wear a mask – wear a respirator that suits the task, for example an FFP3-standard mask or a powered mask or hood if the work is taking longer. If respiratory protective equipment (RPE) is tight fitting, being clean shaven gives a better fit and protection.

- Get trained – understand the dangers of silica dust exposure and when and how to use dust controls and protective equipment.

- Wash hands before eating and drinking – to remove silica dust.

- If you are concerned about dust exposure at work, report it through internal or external channels.

The information above is from No Time to Lose, the Institution of Occupational Safety and Health’s (IOSH) campaign tackling occupational cancer. Raise concerns using appropriate channels, such as your occupational safety and health advisor or CIRAS. Your company may ask a qualified occupational hygienist to measure dust levels.

Try the silica dust ‘fake or for real’ quiz

Close up: ballast dust

Network Rail set up the Ballast Dust Working Group in 2012 as a cross-industry group to identify, mitigate and manage risks on the railway linked to ballast and stoneblower dust and aggregate.

Since its beginnings, the group’s members – including Network Rail and other CIRAS members Morson International, TXM Plant, VolkerRail, Babcock International, APPSUK and Balfour Beatty Rail Services – have been investigating and putting into practice ways to reduce exposure to ballast dust on the railway.

The group has supported initiatives including:

- a ballast dust check reporting sheet, to aid ballast dust complaint investigations

- ongoing tests with ballast dust stabilisers (chemical products to help reduce the release of ballast dust during operations)

- an ongoing initiative to make sure plant and on-track machines build in requirements for water suppression to manage dust

- a ballast rinsing plant at the railhead loading point at Tarmac’s Mountsorrel Quarry

- changes to how ballast is produced and loaded at the railhead at Midland Quarry Products’ Cliffehill Quarry – including changes to the cleanliness of water needed for rinsing the ballast and an Air Knife that removes excess water during ballast loading.

With thanks to Nigel Bownes of Network Rail.

Useful contacts

No Time to Lose campaign

W: notimetolose.org.uk

From IOSH. More resources – including fact cards to share, case studies and talking points for discussions.

Work Right: Dust Kills campaign

W: workright.campaign.gov.uk/campaigns/construction-dust/

From HSE and BOHS.

Breathe Freely campaign

W: breathefreely.org.uk

From the British Occupational Hygiene Society (BOHS).

Track Safety Alliance

Watch the video ‘The Ballast Dust Story’.

Network Rail Safety Central

Download the silica dust safety discussion pack and other materials on the silica safety page.

Asthma + Lung UK

T: 0300 222 5800

W: asthmaandlung.org.uk

E: helpline@asthmaandlung.org.uk

Find local support groups, call the helpline or get information on managing lung conditions.

Health and Safety Executive (HSE)

W: hse.gov.uk/construction/healthrisks/cancer-and-construction/silica-dust.htm

Exposure limits and COSHH (control of substances that are hazardous to health).

NHS

W: nhs.uk/conditions/lung-cancer

nhs.uk/conditions/silicosis

About lung cancer and silicosis.

Tags

- Hazardous Substances

- Health and Wellbeing

- Person's Environment